Unlock Faster, Brighter, More Affordable Textile Dyeing with Pure Anhydrous Sodium Sulfate

In the competitive global textile market, dyers face a constant triple challenge: achieving perfect color consistency, reducing production costs, and meeting stringent sustainability goals. While often overlooked, the choice of auxiliary chemicals is a strategic decision that directly impacts your bottom line and product quality. Among these, anhydrous sodium sulfate (Na₂SO₄) stands out as an indispensable, precision tool for superior dyeing results. Far from being a simple commodity salt, high-purity grades are a secret weapon for efficient, brilliant, and eco-conscious dyeing. This comprehensive guide explores the science, applications, and undeniable benefits of specifying pure anhydrous sodium sulfate from a trusted manufacturer like YRC.

1.Why Purity Matters: The Foundation of Superior Dyeing

For dyers, the choice of anhydrous sodium sulfate is decisive. The industrial standard is the anhydrous form—a white, crystalline powder valued for its 100% active content and reliable performance, unlike its hydrous counterpart (Glauber’s salt).

The true differentiator, however, is purity. Not all grades are created equal. Low-grade sulfate introduces destructive contaminants that sabotage the dyeing process:

Iron (Fe): Degrades dyes, leading to dull shades and yellowish discoloration.

Calcium & Magnesium (Ca/Mg): Form insoluble precipitates with dyes, creating spots, streaks, and wasting expensive colorants.

Insoluble Matter: Deposits directly onto fabric and clogs sensitive dosing machinery, causing downtime.

Investing in high-purity anhydrous sodium sulfate is your primary strategy for achieving flawless fabric quality, maximizing dye yield, and minimizing costly production errors and re-dyes.

2.Mastering Dye Exhaustion: The Electrochemical Advantage

For dyers using anionic dyes (reactive, direct, acid), anhydrous sodium sulfate is the key to controlling dye exhaustion through electrochemistry.

The core challenge is electrostatic repulsion: both cellulosic fibers (like cotton) and anionic dye ions carry negative charges in water, preventing effective attachment. Na₂SO₄ solves this. Upon dissolution, it releases a cloud of positive sodium ions (Na⁺) that swarm the fiber surface, effectively neutralizing its negative charge (reducing zeta potential). This eliminates the repulsive barrier, allowing dye molecules to approach uniformly and bond deeply through van der Waals forces and hydrogen bonding.

This grants Na₂SO₄ a crucial dual benefit. It initially acts as a retardant, ensuring a slow and level initial strike to avoid unlevelness (striping). Then, it vigorously promotes full exhaustion, maximizing color depth and yield.

Why choose Na₂SO₄ over common salt (NaCl)?

Higher Efficiency: The divalent sulfate ion (SO₄²⁻) is more effective per molecule than monovalent chloride (Cl⁻), often requiring less product.

Reduced Corrosion: It is significantly less corrosive to stainless steel dyeing machinery, protecting your capital investment and slashing long-term maintenance costs.

3.Optimizing Processes: Versatile Applications Across Dye Types

Anhydrous sodium sulfate is a versatile workhorse, critical to numerous dyeing applications by managing dye exhaustion and migration.

Reactive Dyes (Cellulose Fibers): This is its most critical application. Prior to alkali fixation, Na₂SO₄ is essential for exhausting dyes onto cotton, rayon, or linen. Typical usage ranges from 20 to 100% owf (on weight of fabric), added in portions to ensure utterly uniform exhaustion.

Direct Dyes (Cellulose Fibers): It directly counteracts the poor exhaustion of direct dyes, significantly enhancing color yield and wash fastness, allowing for deeper shades with less dye.

Acid Dyes (Protein & Polyamide Fibers): On wool, silk, or nylon, its role shifts to a retarding leveling agent. It competes with dye molecules for fiber sites, ensuring a slow, even build-up of color critical for achieving barre-free dyeing on synthetics like nylon.

Vat Dyes & Printing: It acts as an electrolyte for vat dye exhaustion and helps regulate viscosity in printing pastes to prevent premature migration, ensuring sharp print definition.

4.The Strategic Advantages: Boosting Your Bottom Line

Beyond the dye bath, anhydrous sodium sulfate delivers immense operational value, driving profitability and efficiency.

Slash Dyeing Costs: By achieving near-total dye exhaustion (often >90% for reactives), it drastically reduces consumption of expensive dyes, directly lowering your cost per meter/kg of fabric.

Eliminate Costly Re-dyes: Its superior leveling capability is your best defense against unlevel dyeing. This dramatically increases your Right-First-Time (RFT) rate, eliminating the massive waste of water, energy, and time associated with reprocessing.

Guarantee Batch-to-Batch Consistency: High-purity material ensures flawless, repeatable results meeting the strict demands of global brands. Its excellent solubility ensures trouble-free operation in automated dosing systems, preventing downtime.

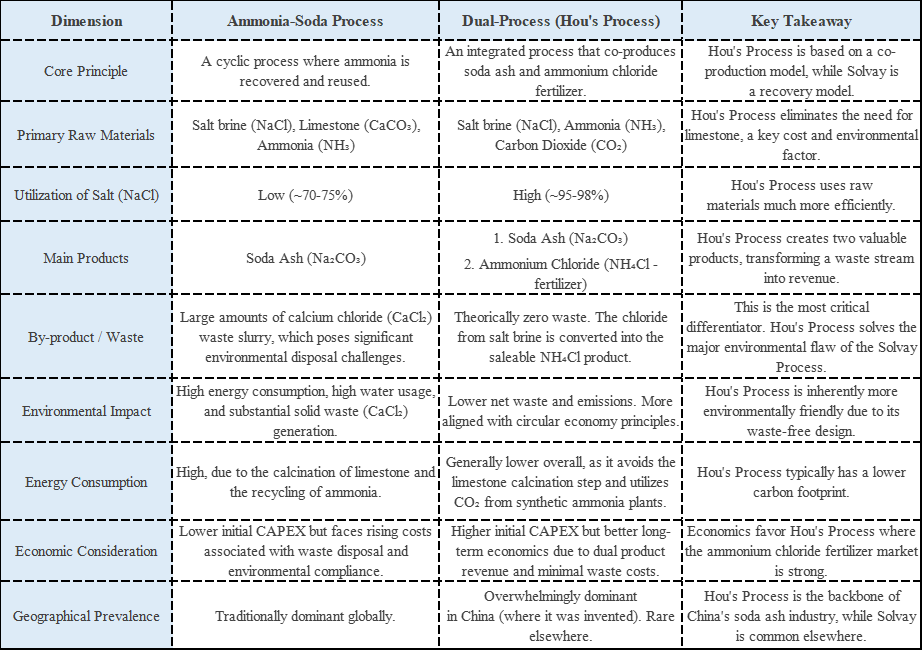

5.Smart Selection: A Guide to Critical Quality Indicators

Compromising on quality is not an option. Specify a product that meets these high standards

At YRC, our anhydrous sodium sulfate is manufactured under strict process controls to not only meet but exceed these specifications. We guarantee a product of exceptional consistency, empowering you to dye with confidence.

6.A Natural Choice for Sustainability

High-purity anhydrous sodium sulfate is a key enabler for greener dyeing, offering immediate environmental advantages:

Inherently Benign Profile: It is non-toxic, biodegradable, and safe. Sulfate ions in effluent are naturally occurring, minimizing ecological impact.

Reduces Environmental Footprint: By boosting dye utilization and slashing reprocessing rates, it conserves critical resources (water, energy, chemicals) and directly shrinks the carbon footprint of your operations.

Guaranteed Compliance: Our product is a reliable component in meeting the requirements of major international standards like OEKO-TEX®, GOTS, REACH, and ZDHC, giving you a competitive edge in eco-conscious markets.

7.Conclusion: Your Partner in Chemical Excellence

Anhydrous sodium sulfate is far more than a simple commodity; it is a scientifically grounded, multifunctional auxiliary critical to the economics, quality, and sustainability of modern textile dyeing. The key to unlocking its full potential lies in partnering with a supplier who understands textile chemistry and provides a product of uncompromising purity.

Ready to optimize your dyeing process and see the difference purity makes?

Contact YRC today to request a sample and discover how our high-purity anhydrous sodium sulfate can become your secret weapon for brilliant, efficient, and sustainable dyeing results. Let our technical experts help you solve specific challenges and improve your bottom line.

YRC – Your Partner in Chemical Excellence.