Anhydrous Sodium Sulfate in Glass Manufacturing: Comprehensive Technical Guide

Anhydrous sodium sulfate (Na₂SO₄), commonly known as salt cake, serves as a multifunctional processing agent in glass manufacturing. This comprehensive technical review examines its critical roles as a fining agent, flux, and process optimizer, with detailed analysis of its mechanisms, benefits, and application-specific considerations for modern glass production facilities.

1. Fundamental Chemical Principles and Reactions

1.1Material Characteristics

Anhydrous sodium sulfate represents the water-free crystalline form of sodium sulfate, characterized by its white, odorless properties and high thermal stability. The compound maintains chemical inertness at room temperature while demonstrating reactive properties under glass melting conditions.

1.2High-Temperature Decomposition Mechanism

At critical temperatures exceeding 884°C, sodium sulfate undergoes precise decomposition according to the following reaction:

Na₂SO₄ → Na₂O + SO₃

The sulfur trioxide further decomposes to sulfur dioxide and oxygen:

2SO₃ → 2SO₂ + O₂

This controlled gas evolution forms the foundation of its fining action, with gas bubble formation commencing precisely at the melt viscosity optimal for impurity removal.

2. Multifunctional Roles in Glass Production

2.1Primary Function: Advanced Fining Agent

The fining capability represents the most valuable property of anhydrous sodium sulfate in quality-critical applications.

Bubble Dynamics and Removal Efficiency

The generated SO₂ and O₂ gases form microscopic bubbles that navigate through the viscous glass melt (typically 10²-10³ poise). These bubbles exhibit remarkable efficiency in coalescing with existing gaseous inclusions, particularly seeds (diameter < 0.1 mm) and blisters (diameter > 0.1 mm).

Process Optimization Parameters

Effective fining requires precise control of multiple factors:

Temperature profile: Maximum efficiency between 1200-1450°C

Dosage optimization: Typically 0.5-1.5% by batch weight

Residence time: Adequate time for bubble migration and removal

Redox control: Critical for predictable gas evolution rates

Quality Impact Assessment

Implementation of proper fining protocols typically reduces visible defects by 70-90%, significantly improving product transparency and mechanical strength.

2.2 Thermal Modification: Fluxing Action Analysis

Melting Point Depression Mechanism: Sodium sulfate actively participates in eutectic formation with silica (SiO₂), establishing lower-temperature reaction pathways. This interaction typically reduces the complete melting temperature by 200-300°C compared to pure silica systems.

Energy Consumption Metrics: The temperature reduction translates to substantial energy savings:

Fuel consumption: Reduction of 10-15% in natural gas requirements

Electrical energy: 12-18% decrease in electric melting operations

Furnace lifetime: Extended refractory life by 15-20% through reduced thermal stress

Environmental Compliance Benefits: Lower operating temperatures correspond directly to reduced NOx and CO₂ emissions, supporting sustainability initiatives.

2.3 Process Enhancement Capabilities

Batch Homogenization Improvement: The hygroscopic nature of high-quality sodium sulfate promotes uniform moisture distribution in the batch, reducing segregation tendencies by up to 40% during handling and charging operations.

Scum Prevention Mechanism: By facilitating earlier silica dissolution, sodium sulfate minimizes the formation of refractory silicate scum, particularly in high-silica formulations. This effect improves melt homogeneity and reduces surface defects.

3. Application-Specific Technical Requirements

3.1 Flat Glass Manufacturing

Purity Requirements: Maximum iron content ≤ 0.005% for optical clarity

Particle Size Distribution: 100-300 μm for controlled dissolution

Typical Dosage: 0.8-1.2% by batch weight

3.2 Container Glass Production

Economic Optimization: Balance between fining efficiency and energy savings

Compatibility Considerations: Coordination with other fining agents (e.g., halides)

Standard Implementation: 0.5-1.0% addition rates

3.3 Specialty Glass Applications

Ultra-High Purity Specifications: Heavy metal content < 10 ppm for technical glasses

Consistency Requirements: Batch-to-batch variation < 2% for optical glasses

Customized Formulations: Tailored particle size distributions for specific melting characteristics

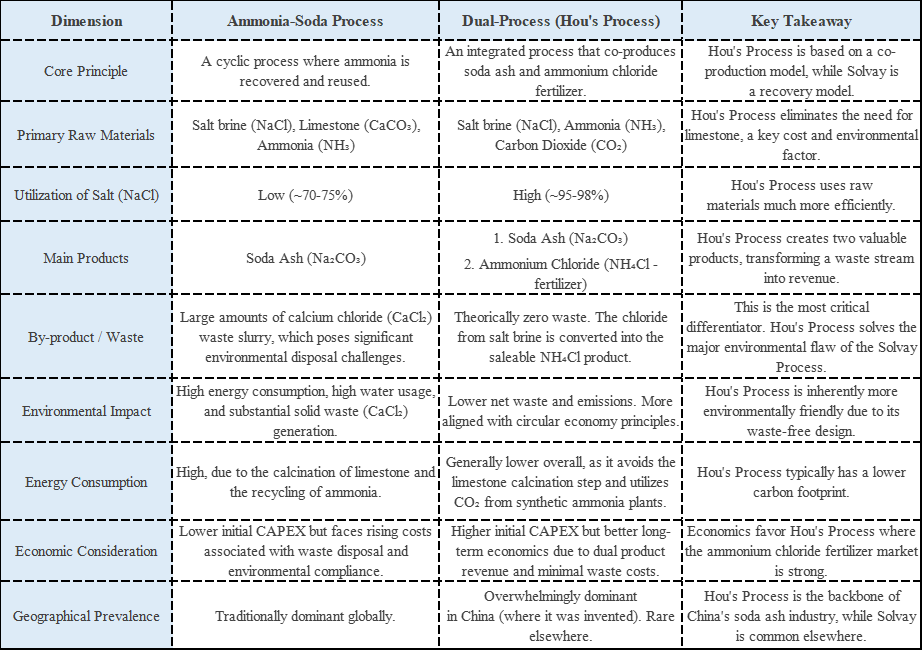

4. Quality Specification Guidelines

4.1 Chemical Purity Standards

4.2 Physical Property Specifications

Bulk Density: 1.2-1.5 g/cm³ for consistent flow characteristics

Particle Morphology: Angular crystals for optimal mixing and dissolution

Loss on Ignition: ≤ 0.2% at 300°C indicating minimal hydration

5. Implementation Best Practices

5.1 Batch Formulation Strategies

Optimal Addition Points: Introduction with other fine components for uniform distribution

Mixing Protocols: Minimum 15-20 minutes in modern mixing systems

Quality Verification: Regular chemical analysis of mixed batches

5.2 Process Integration Considerations

Temperature Program Adjustments: Modification of heating curves to optimize fining

Atmosphere Control: Maintenance of appropriate redox conditions

Quality Monitoring: Implementation of statistical process control for defect tracking

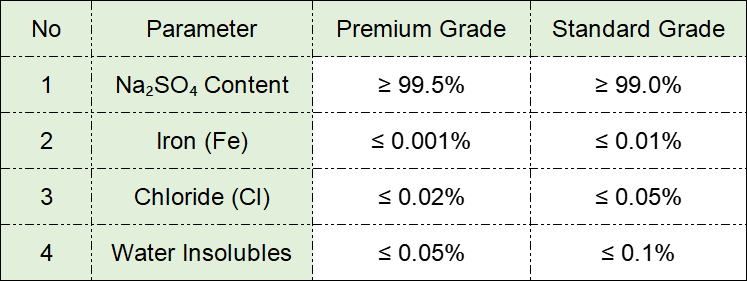

6. Comparative Technical Analysis

6.1 Alternative Fining Agents Comparison

6.2 Economic Justification

Comprehensive cost-benefit analysis typically demonstrates return on investment within 6-12 months through combined energy savings, quality improvement, and extended furnace life.

7. Technical Support and Collaboration Opportunities

Our organization provides comprehensive technical partnership, including:

Batch formulation optimization studies

Process integration assistance

Customized quality specifications

Ongoing technical support and troubleshooting

8. Conclusion: Strategic Implementation Recommendations

Anhydrous sodium sulfate remains an economically and technically superior choice for modern glass manufacturing. Its multifunctional capabilities provide unique advantages in quality enhancement, cost reduction, and environmental compliance. Successful implementation requires attention to quality specifications, process integration, and continuous optimization.

For detailed technical specifications or application-specific consultation, contact our technical team for comprehensive support tailored to your production requirements.