CHEMICAL DRIVEN INDUSTRIAL UPGRADING:six practical areas from production efficiency to green transformation

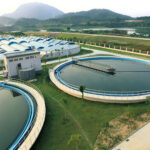

Main application scenarios: Detergent, Papermaking, Printing And Dyeing, Fertilizer, Glass, Water Treatment Industry

Application Areas Include

Chemical additives (surfactants, enzyme preparations) determine their cleaning power and environmental friendliness.

The raw material ratio and melting chemistry determine the strength, transparency, and functionality of glass.

Chemical agents and oxidation technology achieve pollutant degradation, water purification, and recycling.

Dye chemistry and auxiliary technology determine color stability and dyeing efficiency.

The entire process of pulp making, bleaching, and sizing relies on chemical treatment to determine paper properties.

Common Role

Core material supply

Provide production raw materials and functional additives

Process efficiency improvement

Optimize production processes to reduce energy consumption and costs

Green transformation support

Addressing pollution issues and promoting a circular economy

The issues you may be concerned about

The selection of the best product depends on multiple factors, including:

Specific application requirements: What problem do you want to solve?

Target effect: What results do you expect to achieve?

Operating conditions: temperature, pressure, pH value, coexisting substances, etc

Cost effectiveness: Balance between initial costs and long-term benefits

The product price is influenced by various factors, including product type, specifications, order quantity, transportation distance, etc. We offer competitive market prices.

Contact us to learn more