Soda Ash And Anhydrous Sodium Sulfate – Efficient Additives In The Papermaking Industry

Soda Ash and Anhydrous Sodium Sulfate stand as key chemical additives in the papermaking industry, each playing an indispensable role in the pulping and bleaching processes. Their strategic use significantly enhances operational efficiency, improves final product quality, and contributes to more sustainable production cycles, making them invaluable components for modern paper manufacturers.

Soda Ash Dense

Soda ash is a key chemical in the papermaking and pulp making process, especially suitable for alkaline cooking techniques. It is a core additive for the separation and purification of wood fibers.

Soda Ash Light

Soda ash is a key chemical in the papermaking and pulp making process, especially suitable for alkaline cooking techniques. It is a core additive for the separation and purification of wood fibers.

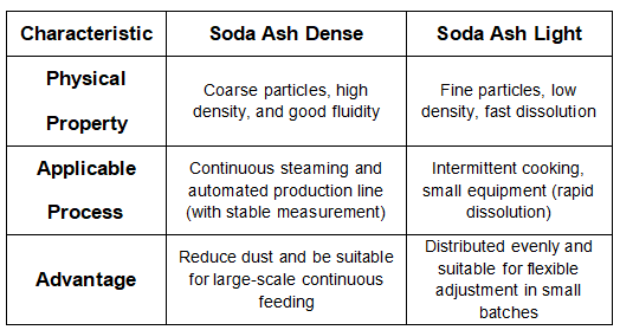

Application differences between heavy and light soda ash

SPECIFIC APPLICATIONS

Pulp making process

The core additive for “delignification”

MECHANISM

Within the pulping digester, lignin undergoes a crucial reaction with soda ash (sodium carbonate), forming soluble sodium lignate salts. This process efficiently facilitates the separation of lignin from the cellulose fibers, effectively liberating the individual fibers for paper production.

MECHANISM

Mainstream bleaching agents need to be effective in alkaline environments with pH 9-11: too low pH can cause bleaching agents to decompose too quickly, resulting in insufficient whiteness; If the pH is too high, the fibers will oxidize and the paper will become brittle. Soda ash slowly releases OH ⁻ by ionizing CO ∝⁻, accurately stabilizing the pH of the system, ensuring bleaching efficiency and inhibiting pulp yellowing.

Whitening process

providing protection for bleaching agents

Whitening process

providing protection for bleaching agents

MECHANISM

The sizing agent is more easily emulsified and dispersed under alkaline conditions, and combines with the hydroxyl groups on the fiber surface to form a water-resistant film; At the same time, soda ash neutralizes organic acids in pulp (such as residual acetic acid from cooking) to avoid acidic environments damaging the fiber structure.

Anhydrous Sodium Sulfate

As an auxiliary electrolyte for sulfate cooking, it enhances pulp efficiency and optimizes pulp properties.

Application Stage

Synergistic effect of sulfate cooking method

Principle: Sodium sulfide can break the ether bonds in lignin, accelerating its dissolution, while anhydrous sodium sulfate serves as a “sulfur source reserve” to maintain stable sulfide concentration in the cooking solution and ensure continuous and efficient reaction.

Pulp washing and concentration

Anhydrous sodium sulfate can adjust the ionic strength of the washing solution, promote the separation of fibers and waste liquid, improve washing efficiency, and reduce the subsequent wastewater treatment load.

APPLICATION EFFECT

The incorporation of Anhydrous Sodium Sulfate delivers significant and measurable benefits to the pulping process. It consistently increases pulp yield by 3-5%, effectively reducing raw fiber loss and material costs. Concurrently, it shortens the required cooking time by 10-15%, leading to substantial reductions in energy consumption and enhanced production throughput. These combined efficiencies make it an exceptionally advantageous additive for producing robust industrial papers, such as high-strength corrugated paper and kraft paper.

PRODUCT ADVANTAGES

Engineered for reliability, high-purity (≥99%) Anhydrous Sodium Sulfate is formulated to safeguard the quality of your paper and the integrity of your production process. By virtually eliminating harmful impurities such as iron and calcium ions, it effectively prevents the discoloration of pulp and avoids costly equipment scaling. This protection is essential for meeting the stringent production requirements of high-end paper goods, including superior-grade writing paper, ensuring both operational excellence and a flawless final product.

FAQ

Have a specific technical question? Contact our experts today for a consultation.