Beyond Cleaning: Sodium Bicarbonate as a Functional Additive in Polymer Production

When most people think of sodium bicarbonate, images of baking, cleaning, or deodorizing come to mind. However, in the sophisticated world of polymer science and plastics manufacturing, this humble compound, also known as baking soda, plays a far more critical and technical role. It serves as a highly efficient, cost-effective, and safe chemical foaming agent (CFA), enabling the production of lightweight, strong, and material-efficient products that are essential in modern industry. This article delves into the science, applications, and significant advantages of using sodium bicarbonate as an indispensable additive in polymer production.

1.The Core Science: How Does Sodium Bicarbonate Create Foam?

The foaming action of this versatile compound is driven by a straightforward thermal decomposition reaction. When heated during standard polymer processing—typically at temperatures between 50°C and 200°C—sodium hydrogen carbonate decomposes, releasing carbon dioxide (CO₂) gas.

The primary decomposition reaction is:

2 NaHCO₃(s) → Na₂CO₃(s) + H₂O(g) + CO₂(g)

This single reaction generates both carbon dioxide and steam, which together act as the powerful foaming gases. For applications requiring a lower decomposition temperature or a higher gas yield, sodium bicarbonate is often used in synergy with acid donors like citric or tartaric acid. The acid-base reaction triggers a more rapid and controlled release of CO₂.

The released gas becomes uniformly dispersed and trapped within the viscous polymer melt. As the plastic cools and solidifies, this creates a consistent cellular structure of tiny, closed cells, which is the hallmark of a high-quality polymer foam.

2.Key Application Areas in Polymer Processing

The unique properties of this foaming agent make it suitable for a wide range of polymer families and processing techniques.

PVC and Polyolefins

This compound is extensively used in extruding PVC (polyvinyl chloride) and polyolefins like polypropylene (PP) and polyethylene (PE). Key products include:

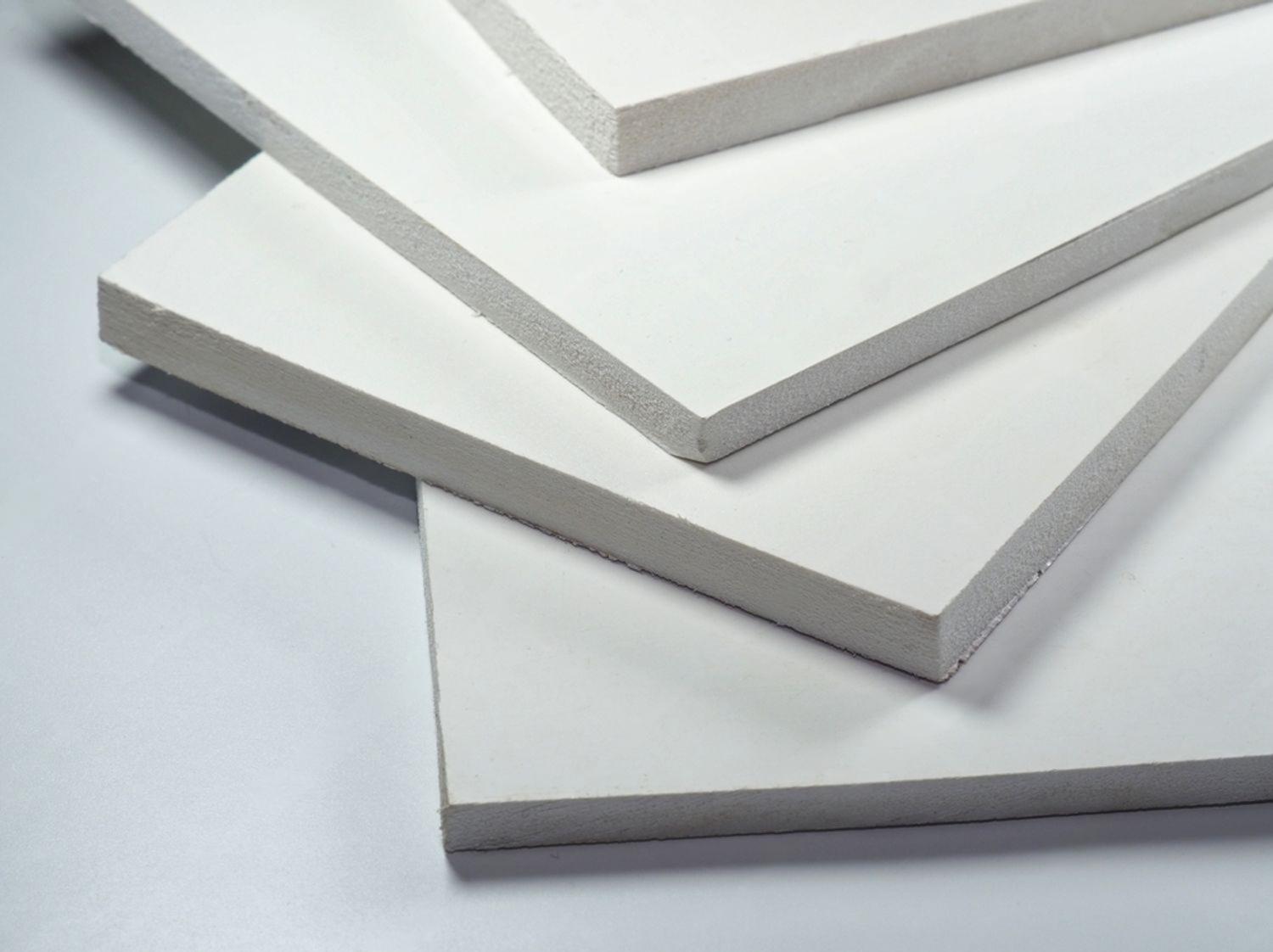

Foamed PVC Board: Lightweight yet rigid boards used in construction, signage, and displays.

Wire & Cable Insulation: Reducing weight and material consumption while maintaining crucial electrical and insulating properties.

Wood-Plastic Composite (WPC): Imparting a lighter weight and a more natural, wood-like texture for decking, fencing, and furniture.

The Rubber Industry

In sponge rubber and EPDM (ethylene propylene diene monomer) rubber, sodium bicarbonate is crucial for producing soft, compressible, and resilient products. These are widely used in automotive seals, gaskets, and weather-stripping for buildings.

Reactive Processing

It also finds important applications in thermosetting polymers. In polyurethane (PU) and phenol-formaldehyde resins, it helps create a fine, uniform foam structure in rigid foams used for thermal insulation and in lightweight molded parts.

3.Competitive Advantages: Why Choose Sodium Bicarbonate?

Manufacturers choose this additive over other foaming agents for several compelling reasons:

Exceptional Cost-Effectiveness: It offers an unbeatable cost-to-performance ratio, providing significant gas yield and foam quality at a low cost.

Inherent Safety: Classified as a food-grade material (E500 in the food industry), it is non-flammable, non-toxic, and safe to handle, which simplifies storage, logistics, and workplace safety compared to some azodicarbonamide-based agents.

Fine, Uniform Cell Structure: It produces a consistent and minute cellular structure, which is critical for achieving superior surface quality, mechanical strength, and insulation properties in the final product.

Dual Functionality: Beyond its primary foaming role, the by-product of its decomposition, sodium carbonate, can act as a mild acid scavenger. This helps neutralize and stabilize the polymer melt during high-temperature processing, particularly in sensitive polymers like PVC.

4.Conclusion: Partner with a Supplier Who Understands Polymer Science

Sodium bicarbonate is far more than a simple commodity chemical; it is a precision tool for polymer engineers seeking to innovate in material design, reduce costs, and improve sustainability through lightweighting. Understanding the nuances of its behavior as sodium hydrogen carbonate under heat is key to unlocking its full potential.

As a leading manufacturer, we provide high-purity, consistent-grade sodium bicarbonate tailored for the demanding needs of the plastics and rubber industries. Our technical team understands the intricacies of decomposition kinetics and particle size distribution, ensuring optimal performance in your specific formulation.

Contact us today to discuss how our advanced sodium bicarbonate solutions can enhance your polymer applications and give your products a competitive edge.