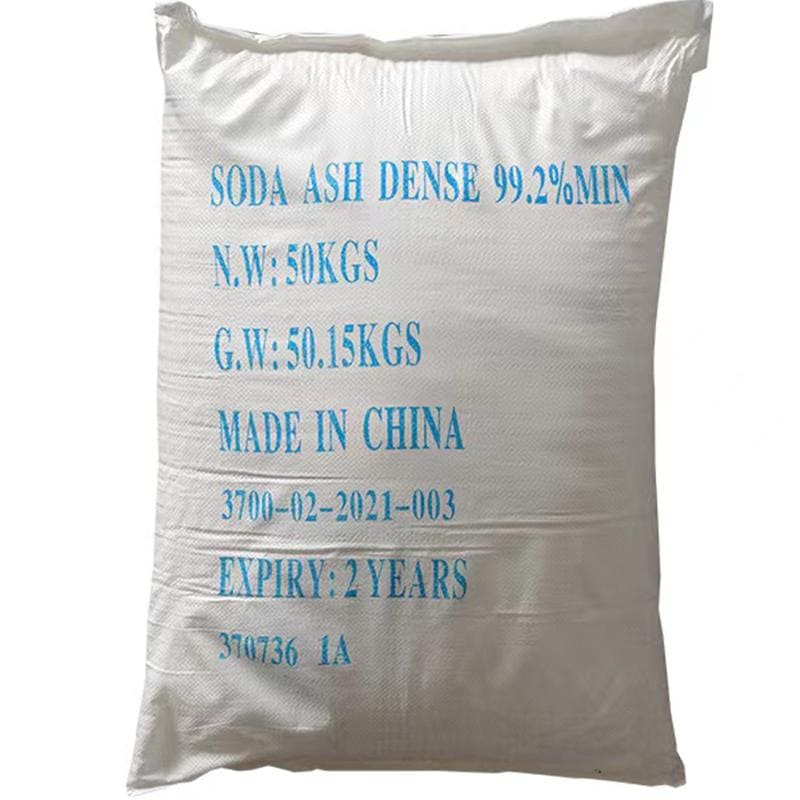

Soda Ash Dense is a vital industrial material valued for its role in large-scale manufacturing processes. Its production is optimized to achieve high density and uniform granular structure, which are critical for streamlining logistics, storage, and downstream processing. Consistent chemical purity and physical stability make it a preferred form in global industrial applications.

CORE FEATURES

Product Advantages

Safety Operation Standards

Fire protection instructions:

This product is non flammable, but it will decompose and produce carbon dioxide and sodium oxide at high temperatures. It will react violently with acid to release carbon dioxide gas. During a fire, water and dry powder fire extinguishers can be used to extinguish it, avoiding direct contact with molten materials (high temperatures may cause container rupture).

Health protection:

Heavy soda ash is an alkaline substance that can cause irritation when in contact with the skin or eyes. Wear alkali resistant gloves, goggles, and dust masks during operation; If accidentally touched, immediately rinse with plenty of water (skin rinse for more than 15 minutes, eyes rinse and seek medical attention).

Storage Conditions

Store in a dry and ventilated warehouse, away from humid environments (humidity ≤ 60%), and avoid storing together with acid, aluminum, and zinc products (to prevent chemical reactions);

The packaging needs to be sealed (it is recommended to use the original packaging), and the stacking height should not exceed 8 layers (25kg bags) to prevent the bottom packaging from being damaged under pressure;

Storage period: It can be stored for 6 months under suitable conditions, and purity and particle size need to be retested if overdue.

Micro design for anti caking: The particle surface is treated with a “silicone coating” (thickness 5-10 μ m) to reduce the adsorption force between particles. It is stored for 3 months in an environment with a humidity of 60%, with a caking rate of ≤ 5%, and does not need to be crushed when poured;

Rapid dissolution particle size distribution: Adopting a “bimodal particle size design”, 30 mesh particles ensure fluidity, 100 mesh particles accelerate dissolution, and the dissolution rate in 20 ℃ water for 5 minutes is ≥ 98% (single particle size products require 8-10 minutes);

Low dust particle hardness: particle compressive strength ≥ 2.5N, crushing rate during transportation and feeding ≤ 3% (about 8% for ordinary products), workshop dust concentration can be controlled below 2mg/m ³.

Note: All packaging can be customized to meet your specific requirements. Please contact our sales team for a detailed quotation and solution tailored to your special requirements.

FAQ

Have a specific technical question? Contact our experts today for a consultation.