Decoding Sodium Carbonate Quality: Beyond Basic Purity

For industry professionals, a 99.5% purity rating for soda ash is a starting point, not a final guarantee. True performance and cost-efficiency are determined by deeper specifications hidden within the data sheet. Understanding these parameters transforms procurement from a routine task into a strategic decision that impacts your product quality and bottom line.

This guide deciphers the critical quality indicators that differentiate standard sodium carbonate from premium, application-engineered material.

Key Parameters Defining Performance

Iron: The Clarity Killer

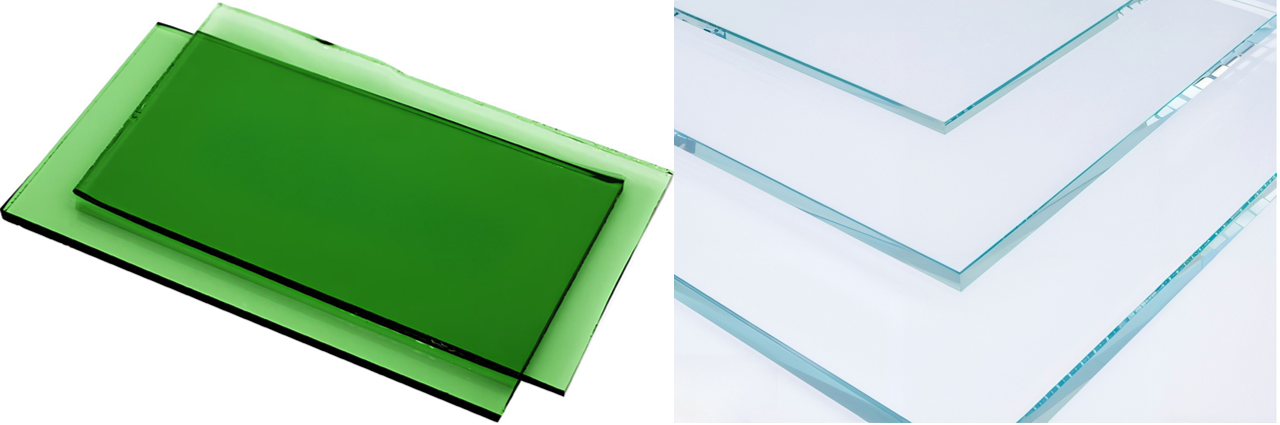

Iron is the most critical impurity in glass manufacturing. Trace amounts act as a colorant, imparting a greenish tint that compromises clarity.

Impact: For photovoltaic glass, even minimal iron content reduces light transmittance, directly diminishing solar panel efficiency. In container and specialty glass, it affects aesthetic appeal.

The Standard: Premium glass production often requires iron oxide (Fe₂O₃) levels below 0.008%.

Chloride: The Catalyst Poison

In chemical processes, chloride ions can be detrimental. They act as a poison to sensitive catalysts, leading to deactivation, reduced reaction efficiency, and increased operational costs.

Applications at Risk: Processes using precious metal catalysts (e.g., palladium, platinum) are particularly vulnerable.

The Solution: Specifying “low-chloride” or “chloride-free” Na₂CO₃ is essential for protecting catalyst investments and ensuring product purity.

Particle Size: The Architect of Stability

Particle size distribution dictates how the material behaves in mixing, conveying, and reacting. Inconsistency is a root cause of production issues.

Too Fine: Creates dust, leading to product loss and safety concerns.

Too Coarse: Causes segregation in mixes and may not dissolve or melt completely.

Industry Needs:

Glass: Requires uniform size for consistent batching and melting.

Detergents: Needs optimized size for flowability and anti-caking.

Chemicals: Often uses finer grades for rapid dissolution.

Bulk Density: The Efficiency Lever

This parameter directly impacts logistics and handling efficiency.

Cost & Logistics: Higher bulk density means more product per shipment and optimized storage space.

Process Stability: Consistent density ensures reliable feeding in automated production lines, preventing disruptions.

Tailored Solutions by Industry

Photovoltaic Glass: Success hinges on ultra-low iron content and exceptionally uniform particle size to maximize light transmittance and melting homogeneity.

Chemical Production: Low-chloride grades are non-negotiable for protecting catalyst systems and maintaining consistent reaction rates and product purity.

Detergent Manufacturing: Customized particle size and density ensure perfect mixing, free-flowing properties, and a superior consumer experience.

Our Commitment to Precision

At YRC, we are your quality partner. Our capability is built on:

Precision Analysis: Using advanced tools like laser particle analyzers and atomic absorption spectroscopy for exact measurements.

Process Expertise: Implementing strict process controls to guarantee exceptional batch-to-batch consistency.

Customized Solutions: Offering tailored products to meet your unique application challenges.

Conclusion: Quality as Your Advantage

Selecting sodium carbonate is a critical technical decision. Moving beyond basic purity to understand and specify key parameters allows you to transform this essential raw material into a source of competitive advantage through improved product performance and process efficiency.

Ready to optimize your material specifications? Contact YRC’s technical experts today for a tailored solution that meets your precise manufacturing needs.