Efficient & Eco-Friendly: Sodium Bicarbonate for Industrial Cleaning

Sodium Bicarbonate, the versatile specialist, is revolutionizing metal surface treatment and industrial cleaning with its efficient, eco-friendly blasting and cleaning technologies. It offers a powerful solution to the challenges of substrate damage, environmental concerns, and safety risks posed by traditional methods.

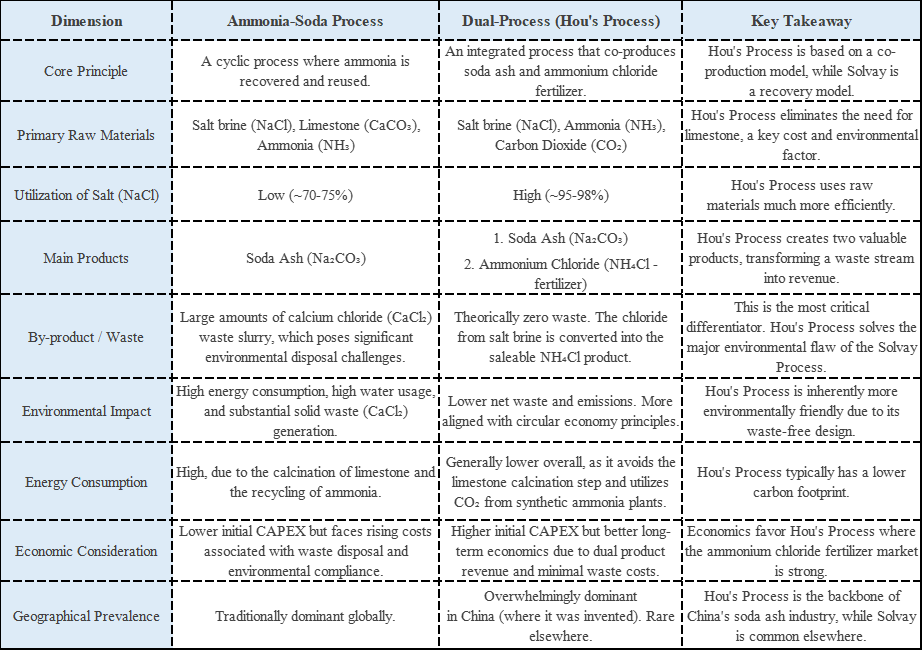

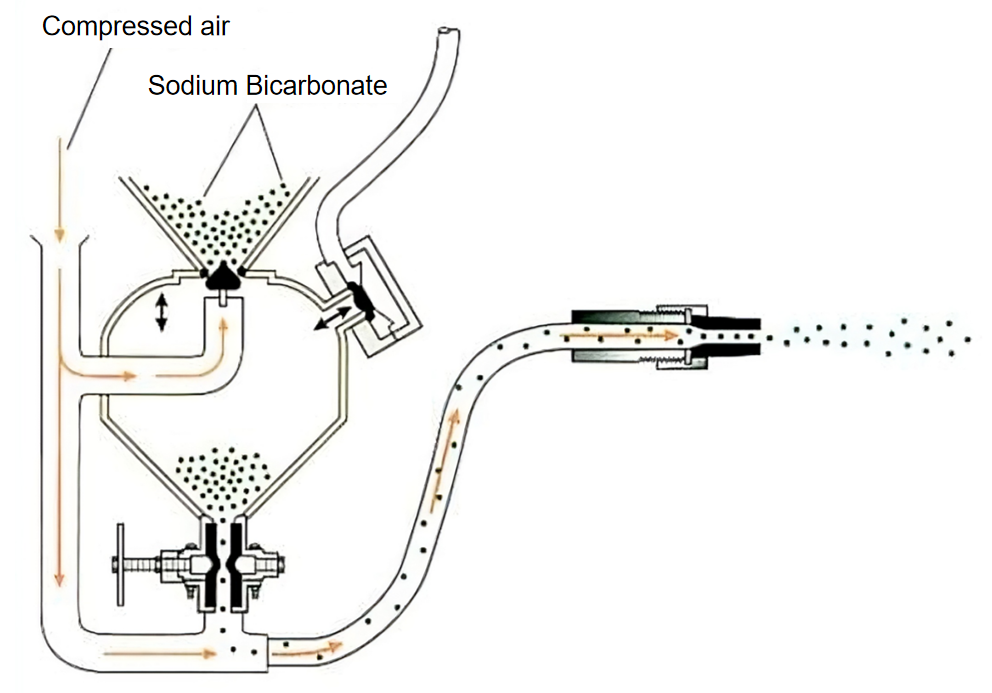

The Core Technology: A Blasting Revolution

Sodium bicarbonate blasting represents a breakthrough in precision cleaning methodology. This advanced technique accelerates micron-sized particles via compressed air, propelling them at high velocity onto the target surface while maintaining exceptional control and safety standards.

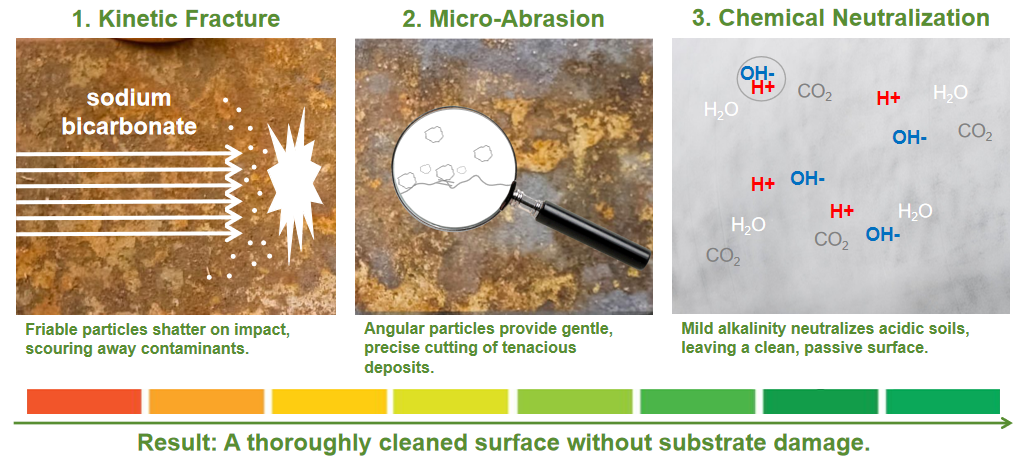

How It Works: The Triple-Action Cleaning Mechanism

Upon impact, a sophisticated three-fold action occurs that sets this versatile compound apart from conventional cleaning methods:

Kinetic Fracture

The friable particles demonstrate unique material behavior by shattering upon impact. This controlled fragmentation creates a scouring action that effectively removes coatings, dirt, and rust without transferring excessive energy to the substrate.

Micro-Abrasion

The angular geometry of the particles provides precisely calibrated cutting action. This microscopic abrasion efficiently eliminates tenacious deposits while preserving the structural integrity of the underlying material.

Chemical Neutralization

The inherent mild alkalinity of baking soda serves as a natural neutralizer for residual acidic contaminants. This chemical action complements the mechanical cleaning process, delivering comprehensive surface purification.

Game-Changing Advantages in Industrial Applications

Substrate-Friendly Processing

The fundamental friability of the particles ensures immediate disintegration upon impact. This characteristic provides crucial protection against wear or peening on sensitive materials including precision metals, delicate molds, and advanced composites, thereby maintaining exact part tolerances throughout the cleaning cycle.

Dry & Minimal Residue Operation

This innovative process operates entirely without water, while its breakdown products consist of water-soluble mineral salts. These compounds can be effortlessly removed using low-pressure air or minimal water rinsing, achieving truly residue-free cleaning outcomes.

Safe & Sustainable Solution

The material’s non-toxic, non-flammable composition and absence of free silica create a safer working environment while protecting operator health. The simplified waste disposal process significantly reduces overall operational costs and environmental impact.

Clean-in-Place (CIP) Capability

This technology enables on-site cleaning of large-scale equipment without requiring disassembly. This feature dramatically enhances maintenance efficiency while minimizing production downtime across various industrial settings.

Key Component in Alkaline Cleaning Solutions

Beyond its blasting applications, sodium hydrogen carbonate serves as a fundamental ingredient in advanced aqueous alkaline cleaning formulations, offering multiple technical benefits.

Operational Operational Mechanism

As a mild alkaline source, it effectively saponifies animal and vegetable fats while neutralizing acidic soils. The compound’s exceptional buffering capacity maintains consistent pH levels throughout the cleaning bath, ensuring reliable and repeatable performance.

Core Value Proposition

Gentle yet Effective Performance

Demonstrating significantly reduced corrosiveness compared to strong alkalis such as caustic soda on numerous metal types, it efficiently removes oils and light rust formations. This action creates an ideal “active surface” for subsequent manufacturing processes including plating, painting, or welding operations.

Enhanced Operational Safety

The powder formulation enables safer handling, transportation, and storage protocols compared to liquid alternatives, reducing workplace hazards and simplifying inventory management.

Superior Biodegradability

The environmentally benign decomposition products align with increasingly stringent environmental regulations, supporting corporate sustainability initiatives and reducing ecological footprint.

Application Scenarios: Solving Critical Industry Challenges

This mild alkaline salt has demonstrated exceptional performance across numerous demanding industrial sectors:

Aerospace Industry Applications

Critical for cleaning turbine blades and airframe components, effectively removing carbon buildup and specialized coatings without compromising the structural integrity of high-value alloy substrates.

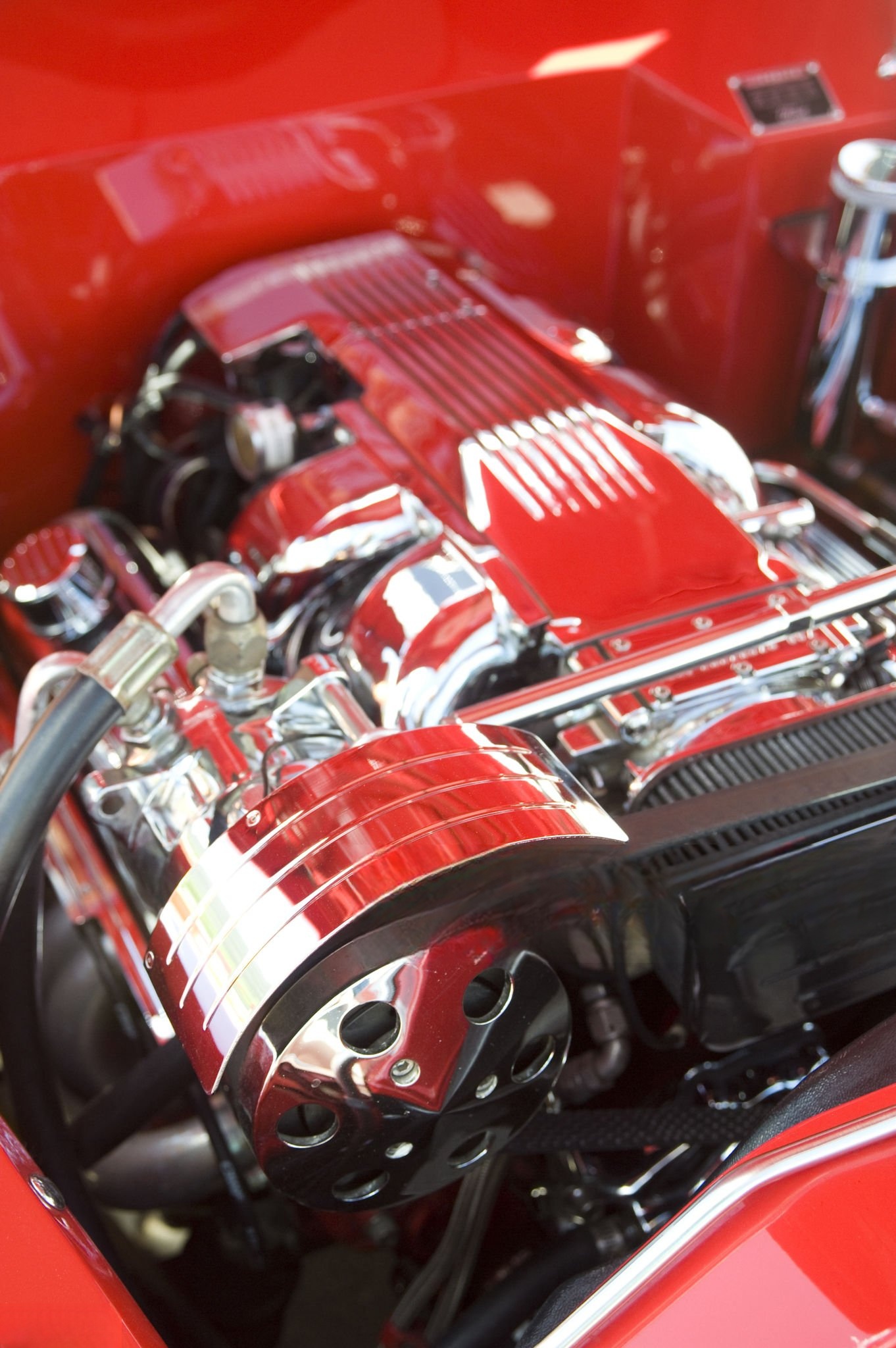

Automotive Manufacturing Solutions

Essential for maintaining engine blocks, transmissions, welding fixtures, and production molds through efficient removal of industrial greases and thermal burn-on residues.

Food Processing Compliance

Safely cleans production line equipment, mixing vats, and processing molds while maintaining compliance with rigorous food-grade safety standards and regulations.

Historic Restoration Projects

Enables gentle removal of corrosion layers and atmospheric contaminants from valuable metal artifacts, preserving their historical integrity and aesthetic value.

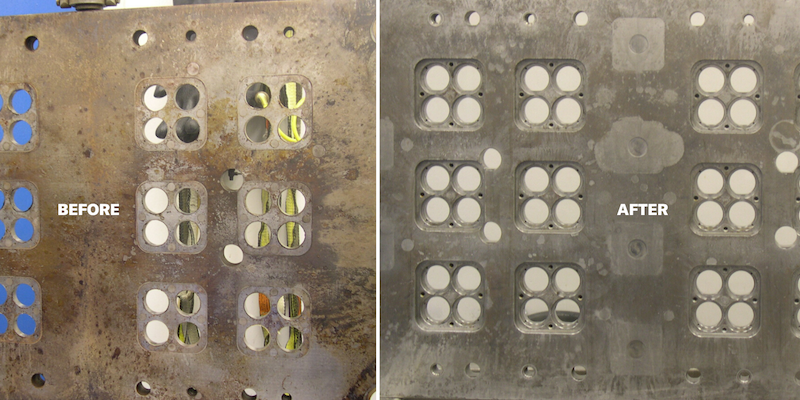

Mold Maintenance Operations

Rapidly strips resin residues and release agent buildup from injection and die-cast molds, effectively restoring critical surface finish specifications and prolonging tool life.

Conclusion: Advancing Toward Intelligent, Sustainable Industrial Cleaning

Whether confronting the challenge of cleaning complex precision components or seeking environmentally responsible alternatives to traditional abrasive blasting, NaHCO₃-based technology represents a sophisticated, safer, and more sustainable direction for modern industrial operations.

We specialize in providing high-quality Sodium Bicarbonate products that consistently meet the most demanding industrial standards, positioning us as your reliable technical partner. Contact us today to discover how to integrate this innovative cleaning solution into your operational processes to enhance quality standards, reduce total operational costs, and strengthen your environmental stewardship commitments.