Meeting Pharmacopeia Standards: The Critical Role of High-Purity Sodium Bicarbonate in Pharma

In the meticulously controlled world of pharmaceutical manufacturing, there is no such thing as a “simple” ingredient. Every component, even the most familiar ones, must meet an uncompromising standard of quality, purity, and traceability. Sodium bicarbonate, a compound ubiquitous in everyday life, undergoes a remarkable transformation in this setting. It evolves from a common chemical into a critical Active Pharmaceutical Ingredient (API) and a versatile excipient, where its quality is directly linked to drug safety, efficacy, and patient outcomes. This article delves into the indispensable roles of high-purity baking soda and explains why sourcing from a cGMP-compliant manufacturer is non-negotiable for pharmaceutical excellence.

1.Sodium Bicarbonate as an Active Pharmaceutical Ingredient (API)

When this compound serves as the primary therapeutic agent, it is rigorously classified and controlled as an API. Its efficacy in these roles is entirely dependent on its high purity and consistent quality.

Rapid-Acting Antacid

Bicarbonate of soda is the key ingredient in many over-the-counter and prescription antacids. Its mechanism of action is the rapid neutralization of excess gastric acid, providing swift relief from conditions like heartburn, acid indigestion, and upset stomach. The reaction is immediate, making it a trusted choice for symptomatic relief.

Systemic Alkalinizing Agent

In critical care and metabolic medicine, the role of sodium bicarbonate becomes life-saving. It is administered intravenously to correct severe metabolic acidosis, a dangerous condition characterized by excessive acid in the blood. Furthermore, it plays a crucial role in managing specific drug intoxications (such from tricyclic antidepressants or aspirin) and is used to control urinary pH to enhance the excretion of certain toxins or to protect the kidneys during chemotherapy.

2.Key Functions as a Multifunctional Excipient

Beyond its role as an API, NaHCO₃’s unique physicochemical properties make it an exceptionally versatile excipient, solving multiple formulation challenges that arise during drug development.

Effervescent Agent

This is one of its most recognizable and valuable roles. In combination with an organic acid (like citric or tartaric acid), it produces carbon dioxide gas upon contact with water. This reaction serves several critical purposes in effervescent tablets and granules:

Enhanced Drug Dissolution: The effervescent action creates a homogenous solution or suspension rapidly, leading to faster absorption and onset of action.

Improved Palatability: The reaction helps mask the unpleasant or bitter taste of many active ingredients, a significant factor in patient acceptance.

Improved Patient Compliance: Offering a pleasant, liquid-like method of administration can be crucial for pediatric, geriatric, or patients who have difficulty swallowing solid tablets.

pH Buffer and Stabilizer

The stability, solubility, and even bioavailability of many APIs are highly pH-dependent. Sodium hydrogen carbonate is used as a buffering agent to precisely adjust and maintain the pH of formulations within a narrow, optimal range. This ensures:

Chemical Stability: Preventing the degradation of the active ingredient over the product’s shelf life.

Physical Stability: Maintaining the clarity, color, and integrity of injectable solutions, topicals, and oral suspensions.

Leavening Agent in Medicated Lozenges

In solid dosage forms like lozenges and chewable tablets, a small amount of baking soda helps create a soft, friable texture that dissolves smoothly and pleasantly in the mouth, significantly improving the patient experience.

3.The Non-Negotiable Importance of Sourcing and Compliance

The margin for error in pharmaceutical manufacturing is zero. Impurities, inconsistencies, or contamination can lead to product recalls, therapeutic failure, or patient harm. This is where global pharmacopeia standards and rigorous quality control become paramount.

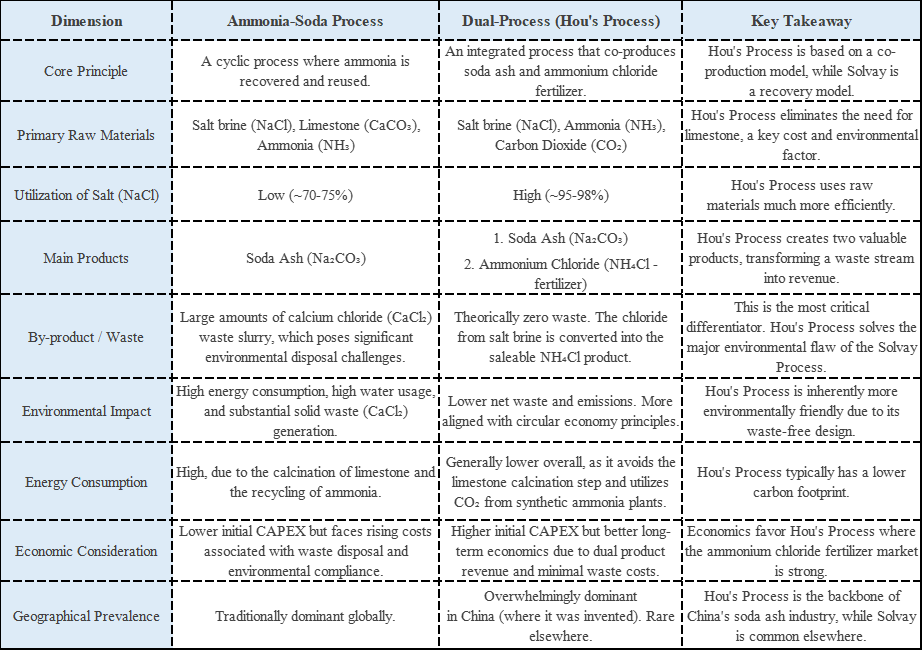

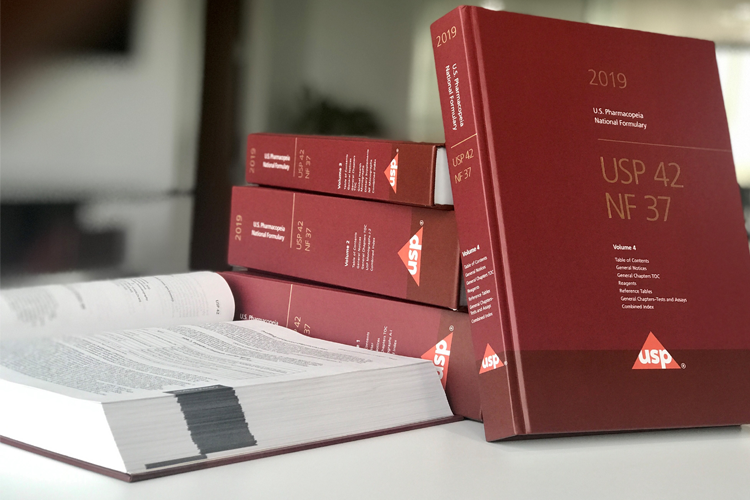

Meeting Global Pharmacopeia Standards

A reputable manufacturer ensures their pharmaceutical-grade NaHCO₃ complies with the strict monographs of major global pharmacopeias, including:

United States Pharmacopeia (USP)

European Pharmacopoeia (Ph. Eur.)

Japanese Pharmacopoeia (JP)

These standards specify strict analytical procedures and acceptance limits for critical aspects like impurity profiles, heavy metal content, arsenic levels, and clarity of solution.

Critical Quality Attributes (CQAs) for Pharmaceutical Grade

Not all sodium bicarbonate is created equal. For pharmaceutical use, several Critical Quality Attributes must be consistently met:

Particle Size Distribution: Consistent particle size is vital for uniform mixing (blending), compaction in tableting, and controlled reaction rates in effervescent products. Inconsistent size can lead to content uniformity issues.

Purity and Impurity Profile: Extremely low levels of heavy metals (e.g., Lead, Mercury) and other impurities are mandated to avoid toxicity, unwanted side reactions, and API incompatibility.

Microbiological Quality: Strict limits on the total microbial count and the absence of specified pathogens like E. coli and Salmonella are essential for patient safety, especially in non-sterile oral products.

The cGMP and Supply Chain Imperative

Consistent, batch-to-batch quality is achieved through adherence to Current Good Manufacturing Practices (cGMP). This comprehensive framework encompasses everything from raw material qualification and controlled, validated manufacturing processes to comprehensive documentation, personnel training, and a fully auditable supply chain. When you source from a cGMP-compliant partner, you are not just buying a chemical; you are receiving a complete quality package that includes full traceability and supporting documentation, such as a detailed Certificate of Analysis (CoA).

4.Conclusion: Your Partner in Pharmaceutical Excellence

In pharmaceutical applications, sodium bicarbonate is far more than a simple ingredient; it is a critical component where quality cannot be an afterthought. Its dual role as both an API and a multifunctional excipient demands a strategic partnership with a supplier who possesses deep regulatory understanding and an unwavering commitment to quality.

As a certified manufacturer, we specialize in producing high-purity bicarbonate of soda that meets and exceeds the stringent requirements of global pharmacopeias. Our products are manufactured in cGMP-compliant facilities, ensuring every batch delivers the consistency, purity, and performance your formulations require.

Contact us today to discuss your specific application needs and to receive a detailed Certificate of Analysis (CoA) for our pharmaceutical-grade sodium bicarbonate.