Optimize Your Supply Chain: The Procurement Guide to Natural Soda Ash

In today’s complex industrial landscape, procurement decisions are about more than just price. Operational efficiency, sustainability goals, supply chain resilience, and product quality are now paramount. For industries reliant on soda ash light and soda ash dense, understanding the fundamental differences between synthetic and natural production methods is a critical strategic advantage. Natural soda ash, derived from mines containing the mineral Trona, offers a distinct profile. It’s noteworthy that Trona ore is uniquely composed of both sodium carbonate and sodium bicarbonate—the primary component of baking soda. For a detailed comparison of these two essential chemicals, see our dedicated article, Soda Ash vs. Baking Soda: The Essential Guide. This comprehensive guide provides an objective analysis of natural soda ash, exploring its properties, benefits, and the global market to inform and optimize your procurement strategy.

Why Choose Natural Soda Ash? Key Properties and Market Advantages

NNatural soda ash, derived from mineral trona ore, offers distinct advantages that make it a superior choice for forward-thinking procurement teams.

Lower Carbon Footprint

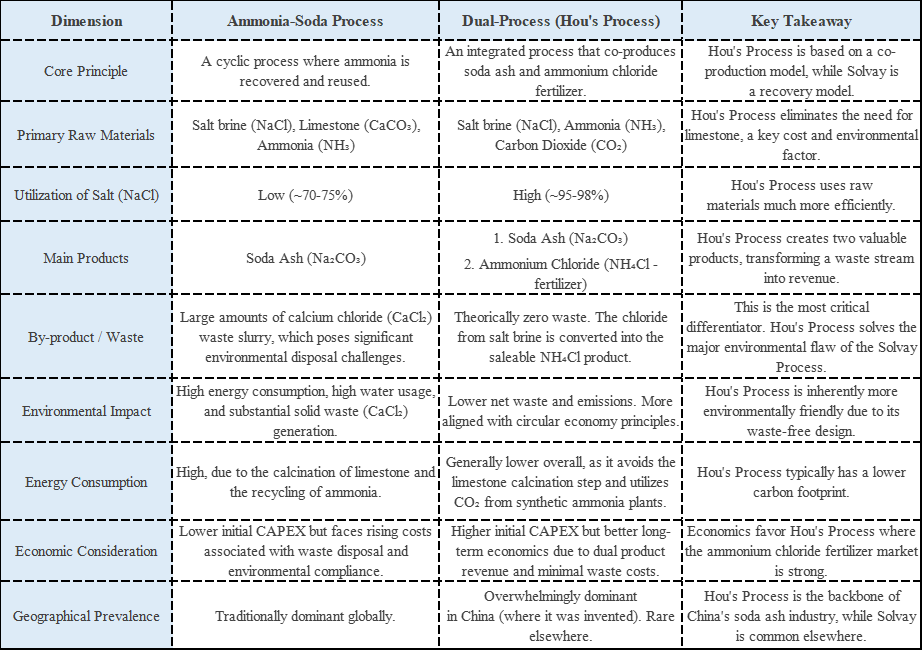

A comparative Life Cycle Assessment (LCA) shows that natural soda ash production generates significantly less CO₂ than the synthetic Solvay (ammonia-soda) process. It eliminates energy-intensive steps like limestone calcination and ammonia recovery. Furthermore, it produces negligible amounts of calcium chloride waste, drastically reducing its overall environmental impact and supporting corporate sustainability mandates.

Stable and Predictable Cost Structure

The shorter, more direct production process insulates natural soda ash from the volatility of energy and raw material prices that often affect synthetic producers. This inherent cost stability provides procurement professionals with greater predictability for long-term budgeting and financial planning.

Superior and Consistent Product Quality

Natural soda ash is renowned for its high purity and low impurity levels. Its dense-grade variant, characterized by a uniform particle size and high bulk density, is particularly valued by demanding downstream industries like flat glass, container glass, and detergent manufacturing, where consistency is non-negotiable.

From Ore to Soda Ash: How Advanced Technology Unlocks Value

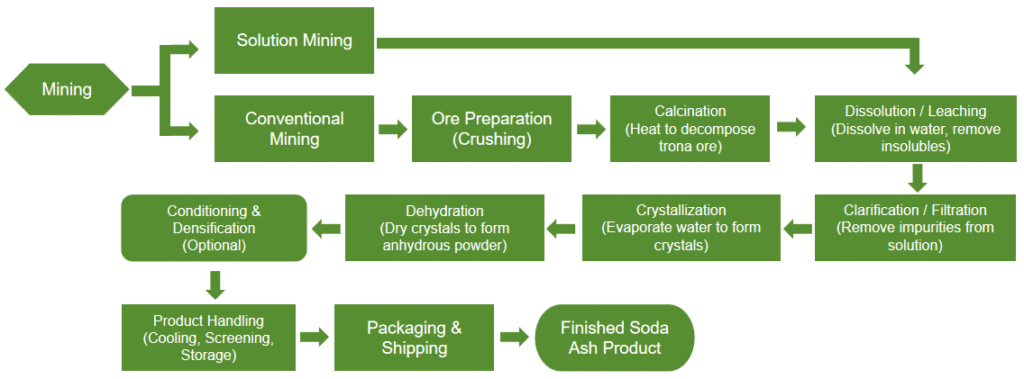

The value of natural soda ash is realized through efficient and technologically advanced production processes. The primary method is solution mining, where hot water is injected into underground trona ore beds to dissolve and extract sodium carbonate-rich brine. This method is far less disruptive to surface ecology than traditional mining.

The extracted brine then undergoes a meticulous series of steps—including purification, evaporation, crystallization, and calcination—to be transformed into high-purity sodium carbonate.

Leading producers invest heavily in continuous technological optimization. The deployment of patented purification technologies and intelligent process control systems allows for precise management of production parameters. This focus on innovation ensures exceptional product consistency, maximizes resource recovery, and enhances energy efficiency, directly benefiting the end buyer.

China’s Pivotal Role in the Global Soda Ash Supply Chain

The global supply of natural soda ash is geographically concentrated, with major production centered in the United States and China. While the U.S. has been a traditional cornerstone, China has emerged as the world’s largest producer and a critical player in the international market, leveraging its vast, high-quality trona reserves.

China’s primary natural soda ash deposits are located in Henan and Inner Mongolia. This region is home to industry leaders like Zhongyuan Chemical and Yuanxing Energy (Boyuan Group), who control some of Asia’s largest trona resources and operate modern, advanced production facilities.

From a procurement perspective, partnering with these established Chinese producers provides access to robust, stable, and high-capacity supply systems. Backed by mature logistics networks and extensive export expertise, these companies guarantee reliable and continuous delivery to major international ports, offering global clients a compelling source of long-term competitive advantage.

Conclusion: Building a Resilient and Sustainable Future

Natural soda ash, with its compelling environmental and economic benefits, represents a strategic asset for companies committed to sustainable development and building resilient supply chains. As global demand grows, China is uniquely positioned to meet this need with scale and efficiency.

For procurement decision-makers, the key to unlocking this value lies in selecting a knowledgeable and reliable supplier—one with deep local expertise, advanced production capabilities, and a broad international vision.

We invite you to engage with YRC as your strategic partner. Contact us today to request detailed product specifications (including soda ash light and dense), access current market analysis, or to initiate a dialogue on how our customized solutions can support your procurement goals and drive your business forward.