Soda Ash Dense: The Backbone of Solar Glass

The photovoltaic (PV) industry stands at the forefront of the global shift toward clean, renewable energy. At the heart of every high-efficiency solar panel lies a critical component: high-transmittance, ultra-strong photovoltaic glass. The production of this specialized glass demands raw materials of exceptional quality and consistency. Among these, Soda Ash Dense (also known as Sodium Carbonate, Dense or Dense Grade Sodium Carbonate) has emerged as the indispensable choice for modern manufacturing. It is far more than a simple raw material; it is a pivotal processing aid that enhances the entire production chain. This article delves into the application details and multifaceted advantages that make dense soda ash the backbone of solar glass.

1. What is Soda Ash Dense? Properties and Production Process

While Soda Ash Dense (Na₂CO₃) and its counterpart, soda ash light, share an identical chemical formula, they differ profoundly in physical form. Dense soda ash is manufactured through a process of hydration, crystallization, and subsequent calcination of light soda ash. This process produces larger, denser, and more uniform granules.

This unique processing yields several key physical characteristics that are critical for industrial applications:

High Bulk Density (>1.0 g/cm³)

Low Dust Generation

Excellent Flowability

Superior Anti-Caking Properties

It is this superior physical profile, not just its chemistry, that establishes soda ash dense as the optimal material for automated, high-volume glass manufacturing.

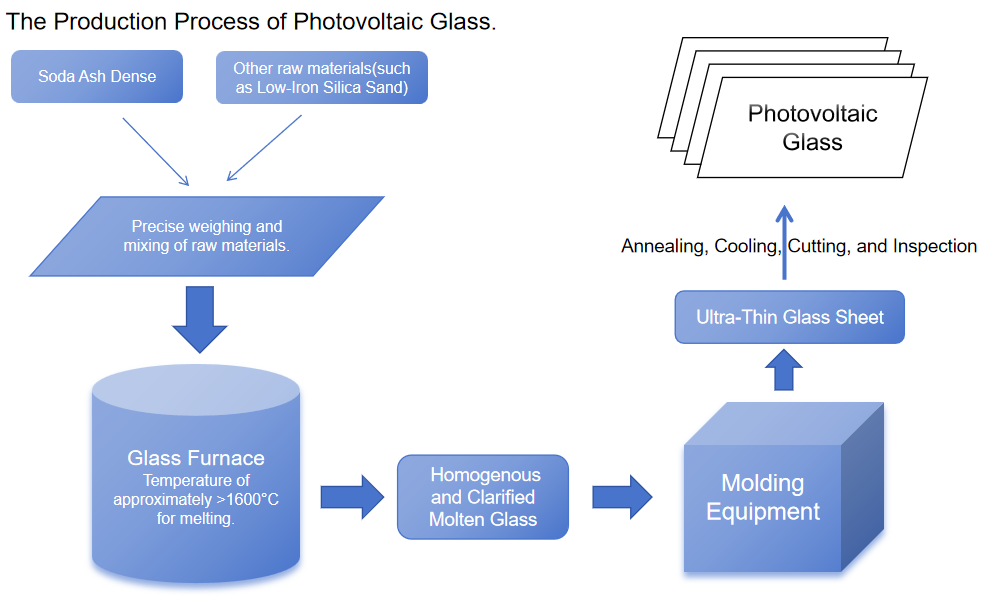

2. Process Implementation: How Soda Ash Dense is Used in PV Glass Production

The application of dense soda ash is integral at every stage of the PV glass manufacturing process, providing tangible benefits from storage to melting.

Batching and Mixing

In the initial batching stage, the excellent flowability and uniform particle size of dense soda ash are crucial. These properties allow for:

Precise Dosing: Enables highly accurate, automated feeding systems, ensuring formulation stability and consistency—the absolute foundation of high-performance glass.

Uniform Mixing: Its granular form allows it to mix more homogeneously with other raw materials (like low-iron silica sand, dolomite, and feldspar), preventing segregation and creating a consistent batch.

Dust Reduction: The low-dust nature significantly minimizes material loss during handling, improves plant air quality, enhances worker safety, and reduces maintenance on equipment.

Melting and Refining

This is where the advantages of dense soda ash become most pronounced inside the glass furnace:

Increased Packing Density: Its high bulk density increases the weight of charge per unit volume in the melter, leading to better heat transfer and improved thermal efficiency.

Faster Melting: The denser batch optimizes the reaction interface with silica sand, accelerating silicate formation and effectively reducing melting time. This directly boosts production efficiency and lowers energy consumption.

Furnace Protection: Reduced alkali flying dust minimizes the corrosive erosion of expensive refractory bricks and heat recovery systems, thereby extending the furnace campaign life.

Homogenization and Forming

The batch uniformity and melting stability provided by dense soda ash are essential downstream. A more homogeneous melt leads to more effective refining (removal of bubbles) and a stable glass composition. This results in fewer defects and directly translates to finished glass with higher optical transmittance and mechanical strength.

3. The Key Advantages of Choosing Soda Ash Dense

Unmatched Performance and Quality

Dense soda ash is fundamental to producing the high-quality glass required by the solar industry.

High Transmittance: It enables the production of glass with light transmittance often exceeding 91.5%. High-purity dense ash has a very low iron content (typically ≤0.015%), preventing iron impurities from tinting the glass and blocking sunlight.

Enhanced Product Consistency: By ensuring a uniform melt, it reduces defects like stones and bubbles, leading to higher production yields and superior product performance that meets the demanding 25-year service life of PV modules.

Significant Economic Benefits

While the per-ton cost may be slightly higher than light ash, dense soda ash delivers a vastly superior Total Cost of Ownership (TCO).

Reduced Consumption: Less fly ash loss during handling and charging means less actual soda ash is needed per ton of glass produced.

Lower Energy Costs: Faster melting rates directly translate to lower energy consumption per ton of glass.

Increased Output: Enhanced melting efficiency can increase overall furnace pull rate and production capacity.

Reduced Maintenance: Extended furnace lifespan and less downtime for repairs lead to substantial cost savings.

Promoting Green and Intelligent Manufacturing

Dense soda ash aligns perfectly with the goals of modern, sustainable industrial operation.

Environmental, Health & Safety (EHS): Its low-dust property drastically improves in-plant air quality, protects worker respiratory health, and reduces the load on emission control systems.

Foundation for Automation: The excellent flowability is a prerequisite for modern, fully automated, enclosed conveying and dosing systems. It is a fundamental enabler for “dark factory” operations and the transition to Industry 4.0 smart manufacturing.

4. Future Outlook

As photovoltaic technology advances, glass continues to evolve toward thinner, larger, stronger, and more transparent products. This trajectory demands ever-higher standards for raw material quality and consistency. Soda ash dense is poised to meet this challenge. Its synergistic effects with other high-purity materials, such as low-iron silica sand, will become even more critical. Continuous improvement in the standards and quality control of dense soda ash will further solidify its role as a strategic material, enabling next-generation PV glass and supporting the continued reduction in the cost of solar energy.

5. Conclusion

Soda Ash Dense is not merely a source of Na₂O; it is a key process technology that elevates every aspect of photovoltaic glass manufacturing. Its superior physical properties—high density, low dust, and excellent flowability—provide a solid foundation for producing high-quality glass in an efficient, cost-effective, and environmentally sustainable manner.

By opting for dense soda ash, manufacturers make a strategic decision that directly strengthens product performance, optimizes operational economics, and enhances market competitiveness. Its role is indispensable in boosting efficiency and reducing costs across the photovoltaic value chain, thereby accelerating the global transition to clean energy and securing a sustainable future.