Sodium Bicarbonate: Revolutionizing Dry Sorbent Injection (DSI) for Industrial Flue Gas Cleaning

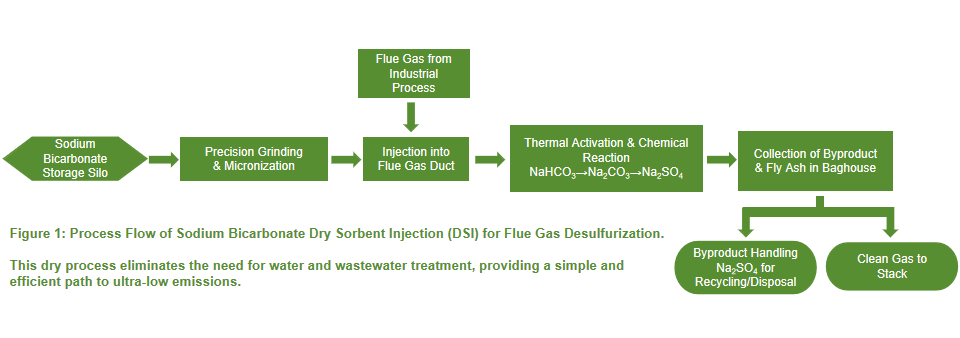

In an era of tightening environmental regulations and increasing pressure for sustainable operation, industries worldwide are seeking more efficient ways to reduce sulfur dioxide (SO₂) emissions. Sodium bicarbonate dry sorbent injection (DSI) has emerged as a powerful, cost-effective, and water-free solution for achieving ultra-low emissions compliance.

1.How Sodium Bicarbonate DSI Works: The Chemistry of Dry Scrubbing

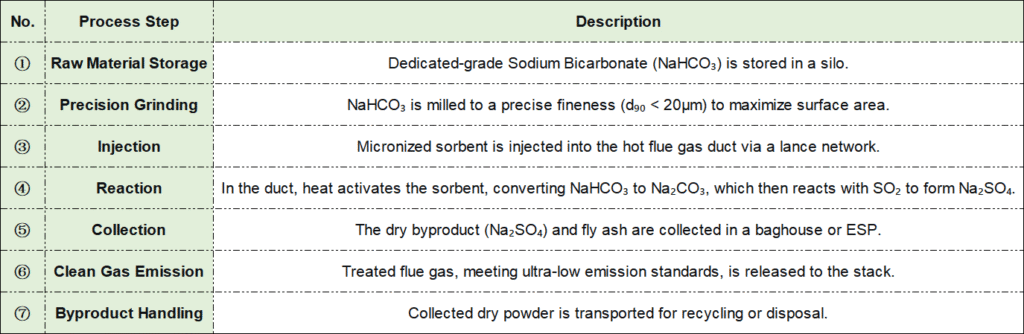

The efficiency of the Sodium Bicarbonate DSI process, as shown in the diagram above, is driven by its straightforward chemistry. The key transformation occurs within the Reaction Duct (Step ④):

Thermal Activation: When micronized sodium bicarbonate (from Step ② & ③) is injected into the hot flue gas (140–180°C / 284–356°F), it rapidly decomposes, forming a highly reactive, porous sodium carbonate particle:2NaHCO₃ + heat → Na₂CO₃ + H₂O + CO₂

SO₂ Capture: This activated sodium carbonate (Na₂CO₃) immediately reacts with sulfur dioxide (SO₂) in the gas stream, converting it into stable and harmless sodium sulfate (Na₂SO₄):Na₂CO₃ + SO₂ + ½O₂ → Na₂SO₄ + CO₂

The solid sodium sulfate byproduct is then Collected (Step ⑤) alongside fly ash in the baghouse, while the cleaned gas is emitted.

This entire Grind → Inject → React → Collect sequence eliminates the need for complex slurry systems and water treatment, providing a dry, efficient, and intelligent path to ultra-low emissions compliance.

2.Key Advantages of Sodium Bicarbonate DSI

High Removal Efficiency

Sodium bicarbonate DSI consistently achieves SO₂ removal rates exceeding 99%, enabling emissions levels below 10 mg/Nm³—well within compliance limits set by the U.S. EPA, EU IED, and other international standards.

Significant Cost Savings

Lower CAPEX: No water tanks, pumps, slurry systems, or wastewater treatment units are required.

Reduced OPEX: Minimal energy, labor, and water consumption lead to ongoing operational savings.

Waterless Operation

As a completely dry technology, DSI eliminates wastewater discharge, making it ideal for regions facing water scarcity or stringent discharge regulations.

Operational Flexibility

The system can be started and stopped instantly, making it suitable for intermittent operations, peak shaving, and backup compliance. Its modularity allows for easy retrofitting in brownfield sites.

Circular Economy Benefits

The reaction byproduct, sodium sulfate, is non-hazardous and can often be sold or reused—for example, in cement or glass production—turning waste into potential revenue.

3.Applications of Sodium Bicarbonate DSI Across Industries

Sodium bicarbonate DSI is not an niche technology—it is a versatile solution successfully applied in numerous sectors:

Waste-to-Energy Plants: Handles variable flue gas compositions from municipal solid waste.

Biomass & Wood Boilers: Effectively controls SO₂ from biofuel combustion.

Glass Manufacturing: Performs well in high-temperature flue gas environments.

Cement & Lime Kilns: Allows in-line treatment and byproduct recycling.

Metallurgical Processing: Capable of treating high-SO₂ streams in sintering and smelting.

Marine Vessels: Used in combination with SCR to meet IMO Tier III standards.

4.Choosing the Right Sodium Bicarbonate for DSI

Not all sodium bicarbonate is equal. For optimal performance in DSI systems, consider the following:

Purity: High-purity NaHCO₃ ensures maximum reactivity and avoids clogging.

Particle Size: Precision milling (e.g., d₉₀ < 20 µm) increases surface area and reaction speed.

Consistency: Reliable supply and quality are essential for uninterrupted compliance.

Companies like YRC offer specially engineered DeSOx-grade sodium bicarbonate that is micronized for rapid reaction and consistent performance, supported by technical expertise and global logistics.

5.The Future Is Dry

Sodium bicarbonate dry sorbent injection represents a paradigm shift in emission control. It offers a simpler, drier, and smarter path to compliance—without the complexity, cost, and water consumption of traditional wet scrubbing.

As regulations tighten and sustainability becomes central to operational planning, DSI stands out as a future-proof solution for SO₂ control.