Sodium Sulfate Anhydrous: The Indispensable Efficiency Booster in Modern Papermaking

In the complex and precise world of pulp and paper manufacturing, every chemical additive is pivotal to the final product’s quality, cost, and environmental footprint. Among these, Sodium Sulfate Anhydrous (Na₂SO₄) stands out as a fundamental, yet often overlooked, industrial workhorse. Also known widely in the industry as Salt Cake, this compound is the “unsung hero” of the Kraft pulping process. This article delves into how Anhydrous Sodium Sulfate empowers paper mills to enhance operational efficiency, optimize product quality, and achieve more sustainable production goals.

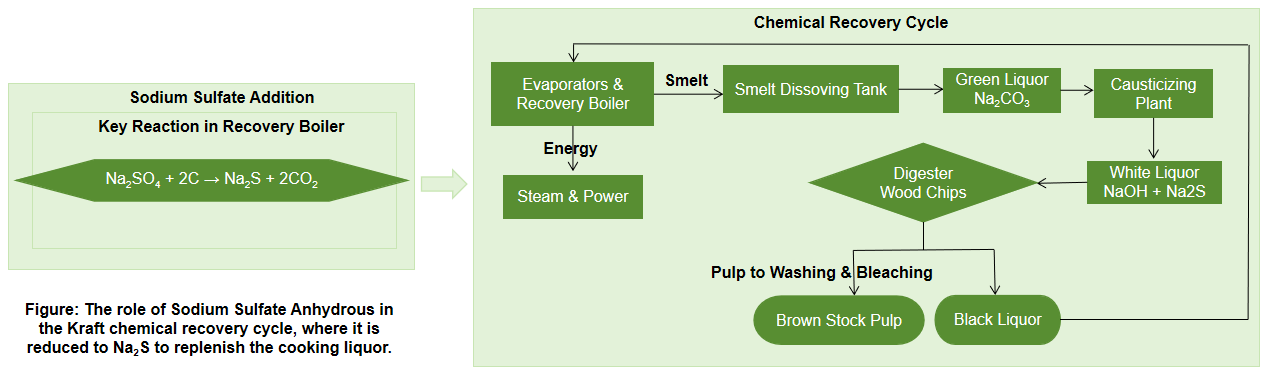

1.The Primary Role: Fueling the Kraft Pulping “Chemical Engine”

The Kraft process is the dominant global method for producing the high-strength pulp essential for corrugated cardboard, brown paper bags, and other robust paper products. Its economic and environmental success hinges on a highly efficient chemical recovery system, and Disodium Sulfate is a core component of this closed-loop cycle.

Mechanism of Action: A Perfect Cycle

During pulping, wood chips are cooked in a highly alkaline solution known as “white liquor,” primarily composed of sodium hydroxide (NaOH) and sodium sulfide (Na₂S). This process dissolves lignin, the “glue” that holds wood fibers together, liberating the cellulose fibers. However, the process consumes sulfur. To maintain the chemical balance and sustain the cycle, a “make-up” chemical is essential. This is where high-purity Sodium Sulfate Anhydrous proves invaluable.

It is introduced into the chemical recovery boiler, where at high temperatures, it is reduced by carbon to form the crucial sodium sulfide (Na₂S):

Na₂SO₄ + 2C → Na₂S + 2CO₂

The newly formed sodium sulfide is then combined with recovered sodium carbonate to regenerate the “white liquor,” ready to return to the digester. This creates a remarkably efficient and economical closed-loop system.

Your Core Benefits in the Pulping Process

Sustains Efficient Delignification: Optimal sulfidity levels, maintained by adding Salt Cake, ensure the cooking liquor rapidly and selectively removes lignin while preserving cellulose strength. This results in a higher pulp yield and stronger final paper products.

Reduces Operating Costs: This regenerative chemical cycle dramatically reduces the need to purchase fresh, expensive sodium sulfide and sodium hydroxide, leading to significant direct savings.

Enhances Environmental Performance: By closing the chemical loop, the system minimizes solid waste generation and the release of harmful emissions, helping your mill comply with increasingly stringent environmental regulations.

2.Versatile Applications: The Multi-Role Player in Papermaking

Beyond its primary role in the Kraft pulping recovery cycle, Anhydrous Sodium Sulfate adds significant value in other critical papermaking stages.

Stabilizer in Bleaching Sequences: In elemental chlorine-free (ECF) and totally chlorine-free (TCF) bleaching sequences, residual hydrogen peroxide from an oxygen delignification stage can interfere with subsequent chlorine dioxide bleaching. Adding Sodium Sulfate Anhydrous acts as an effective stabilizer and scavenger, improving the overall efficiency and cost-effectiveness of the bleaching process.

Performance Enhancer for Fillers and Pigments: This versatile chemical serves as a process aid in the production of certain paper fillers like Precipitated Calcium Carbonate (PCC). It is also used as a raw material auxiliary in the manufacturing of key pigments such as Titanium Dioxide (TiO₂), which is critical for creating bright, white paper.

Enabler of Sustainable Production: Through advanced crystallization technologies, sodium sulfate can be recovered and purified from various pulp mill effluents. This allows for internal resource recycling, turning a waste stream into a valuable raw material. This practice not only reduces raw material costs but also firmly aligns your operations with circular economy principles.

3.Quality is Key: Why Purity and Consistency Matter

In the high-stakes environment of Kraft pulping, chemical purity is not just a specification—it directly impacts production safety, equipment longevity, and final product quality. Impurities in your Salt Cake supply can have costly consequences.

Ultra-High Purity Protects Your Critical Assets

Exceptionally Low Chloride Content: Chloride ions are a primary concern for paper mill operators, as they can cause severe stress corrosion cracking in expensive recovery boilers and other equipment. Our Anhydrous Sodium Sulfate is manufactured with stringent chloride control, offering maximum protection for your multi-million dollar assets.

Negligible Heavy Metal Content: Ensuring your pulp and paper products are safe for high-purity applications like food-grade packaging and premium printing papers is paramount. Our product’s minimal heavy metal content helps you comply with global safety and regulatory standards effortlessly.

Low Moisture & Superior Flowability: Our product exhibits extremely low moisture content and a uniform particle size distribution. This ensures precise, automated feeding systems operate smoothly, preventing clogging in silos and guaranteeing uninterrupted, consistent production.

Reliability You Can Build Your Schedule On:

We guarantee consistent physical and chemical properties batch-after-batch, providing you with the stable process conditions needed for optimal paper quality. Supported by robust production capacity and an efficient global logistics network, we ensure you receive a timely and adequate supply, eliminating the risk of production downtime.

4.Conclusion: More Than a Chemical, A Strategic Partner

Sodium Sulfate Anhydrous, or Disodium Sulfate, is far more than a simple commodity chemical. It is a key enabler of the efficiency, economy, and environmental sustainability that define modern papermaking. Therefore, choosing a technically proficient and quality-focused supplier is not just a purchasing decision—it is a strategic one for maintaining your competitive edge.

We are committed to being your most trusted partner, providing not just high-purity Salt Cake, but also the expert support to help you optimize its use.

Contact us today to request a detailed technical data sheet or to speak with our paper industry experts. Let our high-quality Sodium Sulfate Anhydrous inject greater efficiency, reliability, and sustainability into your papermaking process.